What Happened To Shrinky Dinks?

There are few toys that instantly evoke an afternoon of '70s and '80s arts and crafts as much as the iconic and beloved Shrinky Dinks. The charmingly retro art sets use thin, flexible sheets of polystyrene that come with pre-printed designs that can be colored in with markers, acrylic paints, or colored pencils, then cut out using common household scissors. Once your personalized designs were complete, they were placed on a baking sheet to be baked in the oven, where the Shrinky Dinks do indeed shrink and — per the Gelfland Center at Carnegie Mellon University — go down to about a third of their original size. Curiously, they do become nine times as thick as their original width and turn rigid yet keep the color and design of the pre-baked plastic.

Polystyrene is an unusual material because rather than melting or softening when exposed to high temperatures, it shrinks, but its mass remain the same and the decrease in area is made up for by the increase in thickness. This makes it a fun and functional material that lends itself to creative use. In 1973, two friends recognized the artistic possibilities of polystyrene and developed pre-packaged kits to sell to the public.

Shrinky Dinks started as a Cub Scouts craft project

Shrinky Dinks were invented by Betty Morris and Katie Bloomberg, who met when their sons were in the same Wisconsin Cub Scouts pack in the early 1970s. In a 1999 interview with the Seattle Times, Morris remembered "When we became co-leaders of the pack, we were always looking for unusual crafts the boys could make." Bloomberg had read that people could make "charms" by drawing them on "liver lids," or the polystyrene tops that came with food purchased at delicatessens.

Morris blanched, concerned that putting the plastic in the oven would create a fire hazard, but her fears were unwarranted. "I was wrong! It worked really well! So I thought, 'with a bigger piece of plastic, they could make something interesting.' I was just a housewife; I thought it would be easy to find." Morris and Bloomberg attempted to source larger sheets from a plastics consultant, who originally told them the smallest possible order was 1,000 pounds of polystyrene, but eventually provided them with some sample sheets that they brought back to the Scout troop to see what was possible.

Shrinky Dinks were licensed and went nationwide

The polystyrene crafts were an instant hit. Per Betty Morris during an interview with the Seattle Times, "To our surprise, they just went crazy over it! Those boys fought over every scrap! Katie and I knew right then we ought to form a company." Morris and Katie Bloomberg formed K & B Innovations, decided to name their creation Shrinky Dinks, and began selling kits in 1973 at the Brookfield Square shopping mall in Brookfield, Wisconsin.

Per the Milwaukee Journal Sentinel, the first kits sold for $2 a piece and were hand-assembled by Morris and Bloomberg themselves. After their initial success, they partnered with M.W. Kasch in Mequon, Wisconsin for more streamlined production and distribution, which led to sales of 50,000 kits within the greater Milwaukee area. They went on the license the product to the Colorforms corporation, which produced Shrinky Dink kits using popular characters; the kit featuring the Smurfs (shown above in plastic figurine form) was the biggest seller and Shrinky Dinks mania took off. "Shrinky Dinks just went crazy in the '70s and '80s," said Morris.

The inventor of Shrinky Dinks had to change with the times

As reported by the Milwaukee Journal Sentinel, toy company Milton Bradley bought the licensing rights to Shrinky Dinks from Colorforms. Katie Bloomberg sold her share of the business to Betty Morris in the mid-1980s and went on to embark upon a career in politics, including serving as mayor of Brookfield, Wisconsin for 16 years.

In the 1990s, Milton Bradley bought out rival company Parker Brothers, decided to focus on classic board games (examples shown above), and stopped licensing Shrinky Dinks. "In the '90s, it was pretty rough," remembered Morris, who ended up strategizing to keep her business interests afloat. Changing tactics, she rented a building in North Lake, Wisconsin in 1998 and reorganized her company. She granted non-exclusive licensing rights to multiple toy companies while importing large rolls of polystyrene, decades after trying to wrangle smaller sample pieces of the material for the very first Shrinky Dinks. The rolls were then cut and prepared in North Lake and the companies that had licensed Shrinky Dinks had to buy the polystyrene sheets from K & B Innovations.

Shrinky Dinks materials used in nanotechnology

Per Plastics News, Alex Brands acquired Shrinky Dinks in 2014, with executive vice-president Andy Bailen calling Shrinky Dinks "a great brand with a long history. These products are proven sellers." In 2008, K & B Innovations owner Betty Morris estimated that since its introduction to the public, Shrinky Dinks sales had brought in $150 million, per the Milwaukee Journal Sentinel.

Shrinky Dinks' influence has gone on to be surprisingly far-reaching and well beyond the realm of children's art projects. In 2010, Smithsonian Magazine reported on a study out of Northwestern Universe focused on nanotechnology, or the study of the properties of materials on very small scales. Scientists examining and engineering the properties of certain materials use them to print nano-scale patterns. It's now possible to print the patterns onto polystyrene sheets like the ones used for Shrinky Dinks in order to shrink them and examine them on an even smaller scale. Because the process is so cost-effective, laboratories may produce multiple copies of test patterns as needed.

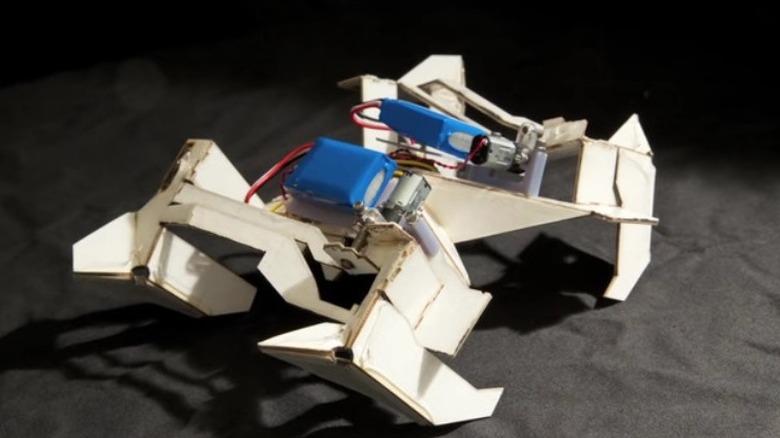

From kitchen crafts to self-assembling robots

In 2014, as reported by Extreme Tech, Harvard University and the Massachusetts Institute of Technology used composite sheets of paper and polystyrene to create the first self-assembling origami robots. Per Harvard scientist Robert Wood, "Getting a robot to assemble itself autonomously and actually perform a function has been a milestone we've been chasing for many years." The origami fold patterns were created by a laser machine system and the patterns' hinges fold when their embedded circuits that produce heat and "tell" the fold to happen. Motors and a microcontroller that knows the fold pattern allow the robots to fold into their predestined shape and walk away.

It's entirely possible that the scientists creating these robots first experienced the principles that make their self-assembly possible while playing with a Shrinky Dinks kit in their childhood. The robots cost just $20 to make, before motors and batteries, and per researcher Don Ingber, "The days of big, rigid, robots that sit in place and carry out the same repetitive task day in and out are fading fast."